What Happens When Quality is Highjacked by a Focus on Growth?

As the largest auto manufacturer in the world, Toyota has been associated with the value of quality for many years – particularly in the minds of North American consumers. Already in the early 1990s, various automotive research firms began rating Toyota among the top automotive brands in terms of quality, reliability, and durability. But it wasn’t always that way.

A Rough Start

When Toyota Motor Corp. entered the U.S. automotive market in 1958 its products were an embarrassment. As one company executive is quoted as saying about the early days of Toyota’s cars sold in America, “Back then, the car was a piece of junk.” With nowhere to go but up, management focused on quality as their top priority. As quality improved, so did sales.

When Toyota Motor Corp. entered the U.S. automotive market in 1958 its products were an embarrassment. As one company executive is quoted as saying about the early days of Toyota’s cars sold in America, “Back then, the car was a piece of junk.” With nowhere to go but up, management focused on quality as their top priority. As quality improved, so did sales.

By 1970, Toyota’s share of the U.S. car and light-truck market had grown to 2%, which wasn’t much when compared to General Motor’s (GM) dominant market share of 40%. By 1980, Toyota’s market share had risen to 3%, and then to a whopping 8% by 1990. It wasn’t until 2006 when the Japanese automaker finally crossed into double digits, it achieved 13% market share. By comparison, GM’s share had shrunk to 26%.

How does Toyota explain this slow model of growth? Some suggest it is best captured by the Japanese word jojo, which means “slowly, gradually, and steadily.” Yet, with the dawn of the 21st century, the company’s growth curve increased exponentially, achieving a major milestone in 2008. With the final tally of global vehicle sales that year, Toyota became the largest automotive manufacturer in the world. This was the first time any automaker had surpassed General Motors in 77 years. To top it all off, Toyota was also the most profitable automaker (while GM and others were suffering billions in losses). It appeared is if nothing could stop the engine of this company, running on its reputation of quality and reliability.

The Quality Crisis

In October 2009, a major crisis began to unfold for Toyota. The company announced the first in a series of highly publicized recalls of vehicles in the United States. The problem cited was “poorly placed or incorrect floor mats under the driver’s seat that could lead to uncontrolled acceleration in a range of models.” The root of this recall was based on the report of a fiery crash in California, where the accelerator of a Lexus sedan got stuck, resulting in the death of 4 people. The recall impacted 3.8 million vehicles. Then, when other reports of unintended acceleration from “sticky gas pedals” surfaced, the National Highway Traffic Safety Administration pressured Toyota to recall additional vehicles and models. Throughout this ordeal, the company recalled more than 7 million vehicles for various issues, including: potentially sticky gas pedals, pedal entrapment, and software glitches that affected braking on some models.

In October 2009, a major crisis began to unfold for Toyota. The company announced the first in a series of highly publicized recalls of vehicles in the United States. The problem cited was “poorly placed or incorrect floor mats under the driver’s seat that could lead to uncontrolled acceleration in a range of models.” The root of this recall was based on the report of a fiery crash in California, where the accelerator of a Lexus sedan got stuck, resulting in the death of 4 people. The recall impacted 3.8 million vehicles. Then, when other reports of unintended acceleration from “sticky gas pedals” surfaced, the National Highway Traffic Safety Administration pressured Toyota to recall additional vehicles and models. Throughout this ordeal, the company recalled more than 7 million vehicles for various issues, including: potentially sticky gas pedals, pedal entrapment, and software glitches that affected braking on some models.

Sadly, the recalls didn’t stop there.

Between February and August 2010, there were 13 separate Toyota recalls, focused on a wide range of issues including steering control and fuel leakage. The company announced two further recalls in early 2011, and in May of that year Automotive News reported that more than 20 million Toyota vehicles had been recalled since the first recall was announced 18 months prior.

What was going on? Did quality suddenly become a problem at Toyota? Did employee competence tank? Or did management simply not care about quality any more?

Understanding the Problem

In time, it became clear that Toyota’s overall focus on quality had diminished, and that this problem had started much earlier. There is evidence that safety issues related to unintended acceleration had already appeared in 2002, with a year-over-year increase in customer complaints by more than five fold. By 2007, Consumer Reports had observed a decline in overall vehicle quality, and in 2008 the magazine decided to no longer give automatic “recommended” ratings to all Toyota models based on their previous evaluations. This was a significant move for a publication that many viewed had a 30-year “love affair” with Toyota.

In time, it became clear that Toyota’s overall focus on quality had diminished, and that this problem had started much earlier. There is evidence that safety issues related to unintended acceleration had already appeared in 2002, with a year-over-year increase in customer complaints by more than five fold. By 2007, Consumer Reports had observed a decline in overall vehicle quality, and in 2008 the magazine decided to no longer give automatic “recommended” ratings to all Toyota models based on their previous evaluations. This was a significant move for a publication that many viewed had a 30-year “love affair” with Toyota.

Most significantly, Toyota’s president, Akio Toyoda, highlighted the root of the problem when he made a public statement in March 2010 that the company’s misguided strategic focus warped what he called the “order of Toyota’s traditional priorities.” He essentially acknowledged that quality had been replaced as Toyota’s number one priority. What replaced it, already a decade earlier, was the strategic shift to aggressively increase market-share.

A focus on growth highjacked the value of quality.

When a company grows quickly to become as large as Toyota, it’s not uncommon to see quality suffer.

Consider that at the beginning of 2008 a Toyota executive in charge of technical and regulatory affairs warned fellow executives that “some of the quality issues we are experiencing are showing up in defect investigations (rear gas struts, ball joints, etc.)”. But these and other warnings were ignored because the strategic focus was on growth. Quality had taken a back seat.

Note that a critical attribute of quality management is to identify issues early and eliminate them while they are still minor problems. But as Toyota became the biggest global automotive player, company leaders disbanded a high-level task force in early 2009 that had been set up four years prior to deal with quality issues. An explanation by one Toyota manager for this decision was that management had come to believe that quality control was part of the company’s DNA and therefore they didn’t need a special committee to enforce it.

Clearly, the quality issues Toyota experienced demonstrated that there is no such thing as corporate quality DNA.

Creating a Culture of Quality

But it may be possible to create a culture of quality.

One of the key findings from a 2014 study, titled Culture of Quality, include the following:

One of the key findings from a 2014 study, titled Culture of Quality, include the following:

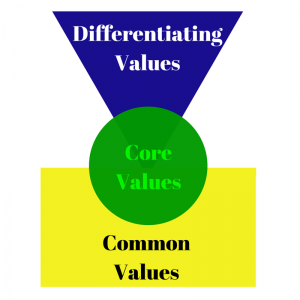

An organization’s “values” can help individuals at all levels make better and more responsible decisions relating to issues of quality. Here [based on survey respondents], only 61% describe their quality values as clearly stated. However, the figure rises to 76% among self-described world-class organizations and again falls for both Europe- and Asia/Pacific-based companies to 50%. Finally, only half, 50%, say such values are clearly understood throughout the organization.

To create a culture of quality, leaders must clearly communicate the organizations values and continually reward and recognize decisions and behaviors that are aligned with the stated values. This is especially important as the organization adapts to competitive challenges, changing consumer tastes, and shifting market conditions.

At Toyota, its leaders experienced the high cost of losing its focus on quality, not only from the cost of recalls and lower sales and market share, but also taking a huge hit to its reputation. To its credit, Toyota implemented numerous countermeasures to fix the quality issues, and put quality back as its #1 priority. These and other measures appear to be working as the company has regained its claim for producing high quality vehicles.

Bottom line

Leaders that embrace excellence or quality as a core value need to recognize that they have entered into a race that never ends. Competitors will forever be raising the bar and customers will always have higher expectations of companies that promise quality. The moment leaders allow something else to take precedent, beware of impending disaster.

The value of quality is not for the faint of heart.