Marketing the True Value of Quality

How many organizations claim ‘quality’ as one of their core values? Many. Many. Many.

How many organizations claim ‘quality’ as one of their core values? Many. Many. Many.

Just consider a few of the organizations that tout quality as a core value:

- John Deere

- Lenovo

- Michigan State University

- Tetra Pak

- Tuality Healthcare,

- USG (building materials)

- Volvo

- Whole Foods Market

Each one of these could be challenged whether quality is making a significant difference in the business and brand. It’s questionable for Michigan State University. But Whole Foods Market is likely doing well with it.

Can their customers see a difference in the quality of products and services versus competitors? All else being equal, does quality set them apart? Is quality creating a competitive advantage?

If an organization wants to set the bar for excellence in their field, to be known as “the best”, then they need to fully embrace the value of quality.

The Value of Quality

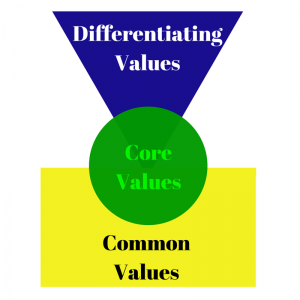

As a differentiating value, Quality means an essential and distinguishing attribute; a degree or grade of excellence or worth. At times, these may seem to be opposing in meaning.

On the one hand, a product that has a smooth, sleek design may be viewed as higher quality. Compare the iPhone to some of the earlier smartphone ‘bricks’ and customers can easily feel the quality of Apple’s products. Sleek design has become a distinguishing attribute for Apple. It also allows them to charge a premium in their pricing.

On the other hand, a product or service might be given an overall grade of excellence that is associated with higher quality. When comparing #1 Harvard University with #189 Andrews University, students expect a higher quality education at Harvard. Students can also expect to pay a higher tuition ($40,000 vs. $24,000) and compete for a tougher acceptance rate (6% vs. 36%).

Not surprisingly, distinguishing attributes tend to be associated more with product quality and grade of excellence tends to be associated more with service quality. But for either products or services, if an organization wants to embrace the value of quality, they need to have some measurement of quality control.

The Shift in Quality Control

In the heyday of the industrial economy where workers lined up along an assembly line, quality control was done at the end of the line. The mission of the Quality Control department was to ensure all products met a “minimum standard of quality” before being shipped out. To save money, the question was “how low can we go?”

The challenges with this model were most visible in the American auto industry. In the 1980s, GM, Ford, and Chrysler were producing very poor quality vehicles when compared to their European and Japanese competitors. It was a huge problem and has taken years to turnaround.

Today, quality is viewed very differently.

For organizations that truly embrace the value of quality, Quality Control engineers are involved at the beginning of the whole process. Their mission is to establish the quality parameters that will create competitive advantage. They also ensure nothing happens along the production pathway that might diminish quality.

Better still, ideas for improvement are encouraged from all employees, and vendors too. In addition, employees are encouraged to get involved along the pathway of quality. All ideas are welcomed.

In the new world of auto production, there are many reports of workers who can push the “stop” button on the assembly line because they see a problem and want to fix it. They’re also encouraged – and rewarded – to bring forward ideas for making things better.

When everyone in an organization – from the executive team to management to individual contributors – takes ownership over quality, then it can indeed be claimed as a differentiating value.

Do you know an organization that has made quality a truly differentiating value? How did they do it?

Could the value of quality give you a competitive advantage? How?

Today’s value was selected from the “Creativity-Uniqueness” category, based on the e-book Developing Your Differentiating Values.